Cell remedy represents a promising new frontier in drugs, particularly in treating ailments comparable to cancers, inflammatory ailments, and power degenerative problems by manipulating or changing cells to revive perform or combat illness. Nonetheless, a serious problem in CTP manufacturing is rapidly and successfully guaranteeing that cells are free from contamination earlier than being administered to sufferers.

Current sterility testing strategies, based mostly on microbiological strategies, are labor-intensive and require as much as 14 days to detect contamination, which may adversely have an effect on critically ailing sufferers who want speedy remedy. Whereas superior strategies comparable to fast microbiological strategies (RMMs) can scale back the testing interval to seven days, they nonetheless require advanced processes comparable to cell extraction and progress enrichment mediums, and they’re extremely depending on expert employees for procedures comparable to pattern extraction, measurement, and evaluation. This creates an pressing want for brand spanking new strategies that provide faster outcomes with out compromising the standard of CTPs, meet the patient-use timeline, and use a easy workflow that doesn’t require further preparation.

This technique affords vital benefits over each conventional sterility checks and RMMs, because it eliminates the necessity for staining of cells to establish labelled organisms, avoids the invasive technique of cell extraction, and delivers leads to below half-an-hour. It supplies an intuitive, fast “sure/no” contamination evaluation, facilitating automation of cell tradition sampling with a easy workflow. Moreover, the developed technique doesn’t require specialised gear, leading to decrease prices.

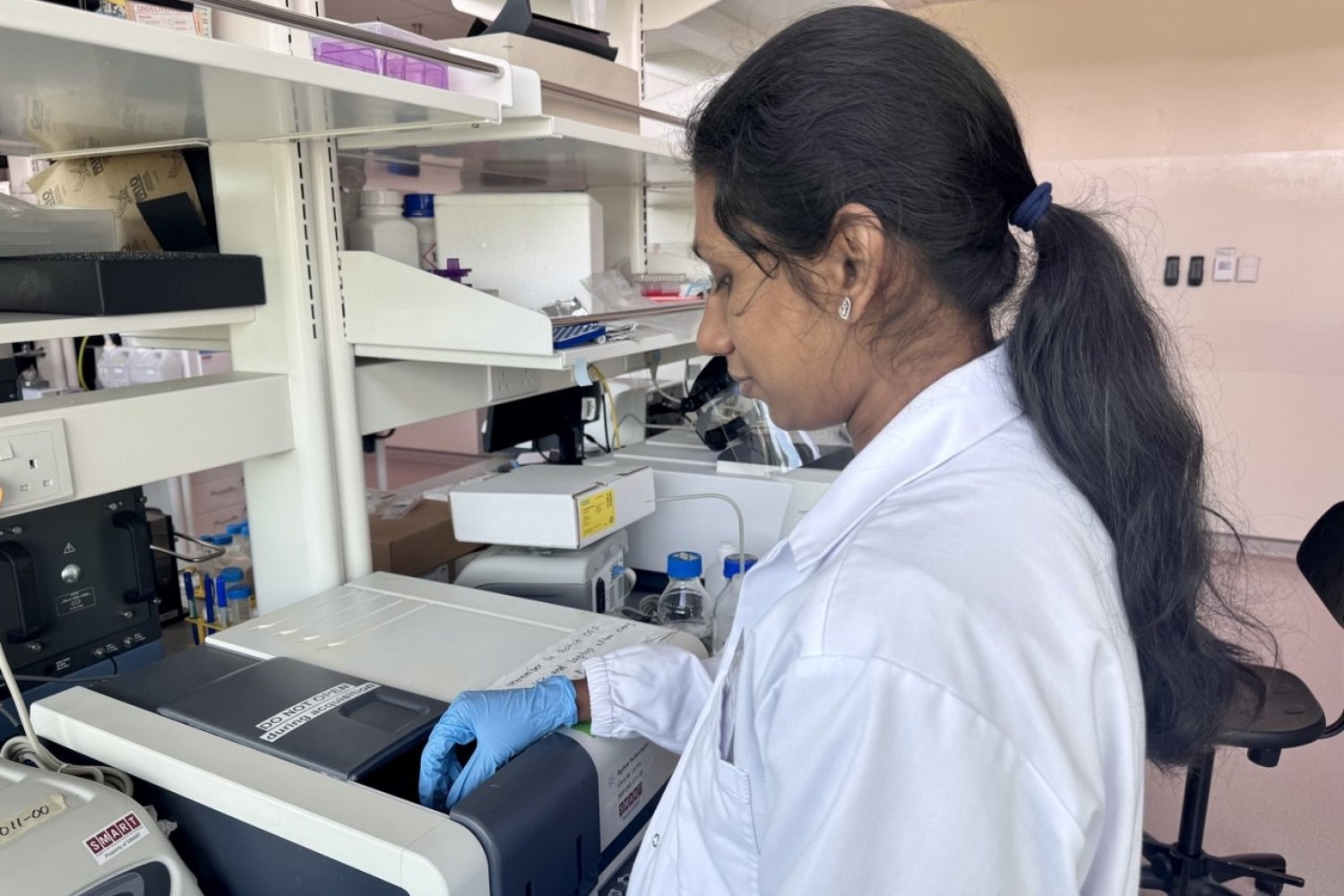

“This fast, label-free technique is designed to be a preliminary step within the CTP manufacturing course of as a type of steady security testing, which permits customers to detect contamination early and implement well timed corrective actions, together with the usage of RMMs solely when potential contamination is detected. This strategy saves prices, optimizes useful resource allocation, and finally accelerates the general manufacturing timeline,” says Shruthi Pandi Chelvam, senior analysis engineer at SMART CAMP and first writer of the paper.

“Historically, cell remedy manufacturing is labor-intensive and topic to operator variability. By introducing automation and machine studying, we hope to streamline cell remedy manufacturing and scale back the danger of contamination. Particularly, our technique helps automated cell tradition sampling at designated intervals to examine for contamination, which reduces handbook duties comparable to pattern extraction, measurement, and evaluation. This allows cell cultures to be monitored repeatedly and contamination to be detected at early levels,” says Rajeev Ram, the Clarence J. LeBel Professor in Electrical Engineering and Laptop Science at MIT, a principal investigator at SMART CAMP, and the corresponding writer of the paper.

Shifting ahead, future analysis will concentrate on broadening the appliance of the strategy to embody a wider vary of microbial contaminants, particularly these consultant of present good manufacturing practices environments and beforehand recognized CTP contaminants. Moreover, the mannequin’s robustness could be examined throughout extra cell sorts aside from MSCs. Past cell remedy manufacturing, this technique may also be utilized to the meals and beverage business as a part of microbial high quality management testing to make sure meals merchandise meet security requirements.

![AI advertising campaigns solely a bot may launch & which instruments pitch the most effective ones [product test]](https://blog.aimactgrow.com/wp-content/uploads/2025/06/ai-marketing-campaigns.webp-120x86.webp)